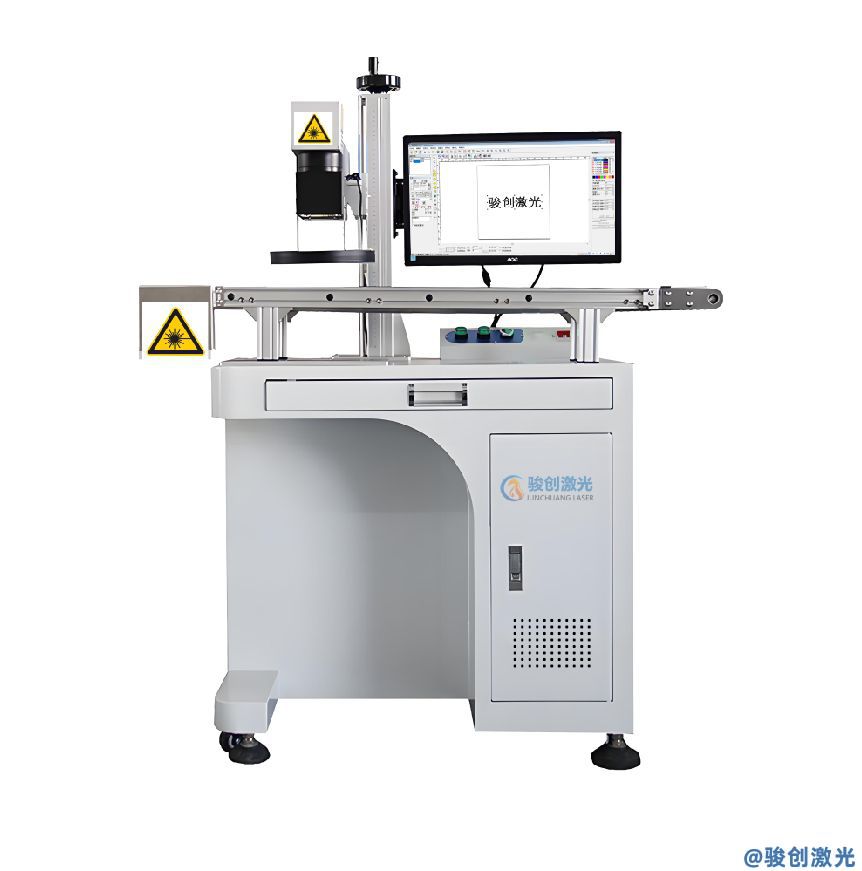

Products Description

A Visual Laser Marking Machine is an advanced laser marking system that integrates vision technology with laser engraving, offering high precision, flexibility, and automation. It typically uses a combination of high-speed scanning galvo, a laser source (fiber, CO?, or UV laser), and a camera or visual system for precise alignment, positioning, and quality control during the marking process.

Key Features

Vision Alignment System:

- The core advantage of a visual laser marking machine is its vision alignment system, which uses a camera to visually detect and recognize the position of the workpiece. This allows the machine to adjust the laser marking location for more accurate and consistent results, even when the objects are irregular or misaligned.

- It is especially useful for automatic positioning of objects, even when they are not perfectly oriented or fixed.

Precision and Accuracy:

- With the aid of the vision system, the machine can precisely mark complex and intricate designs with very high accuracy.

- The visual system enhances the machine’s ability to perform high-precision tasks, such as fine engraving, marking, and cutting, on a variety of materials, including metals, plastics, ceramics, and more.

Flexible and Automated:

- The visual laser marking machine allows for automatic alignment and adjustment based on the image recognition of the target objects, reducing the need for manual positioning and operator intervention.

- It improves productivity by ensuring that the machine can mark multiple items at different orientations or in varying positions without manual adjustment.

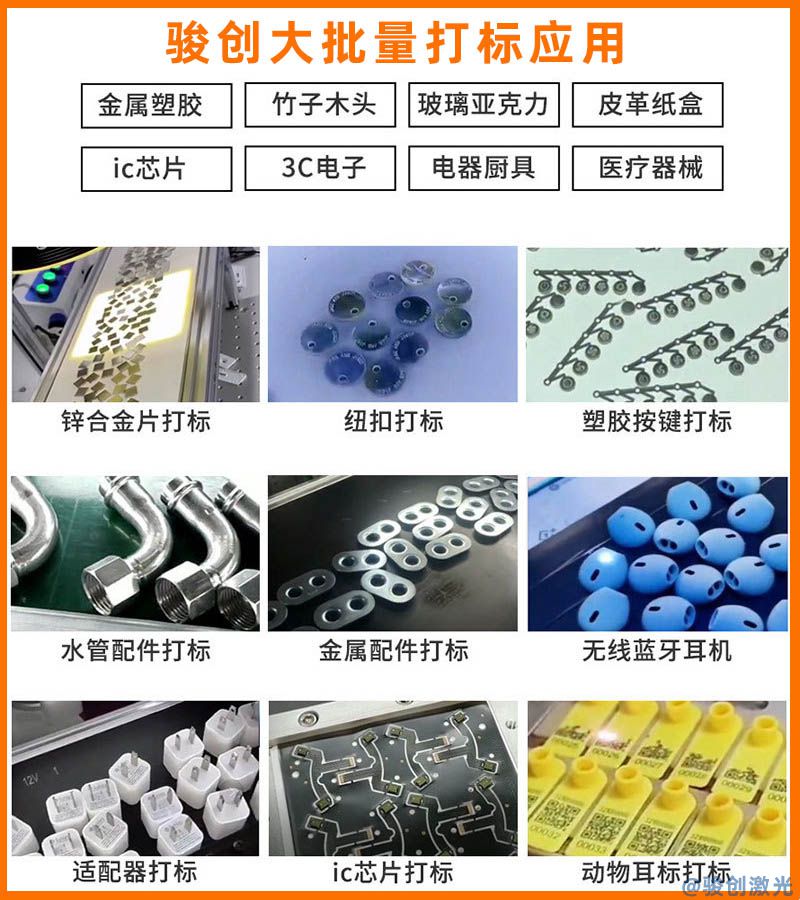

Versatile Application:

- Electronics Industry: Used for marking components like PCBs, capacitors, resistors, etc.

- Medical Devices: For engraving serial numbers, logos, or other critical information.

- Automotive Industry: Marking parts like engine components, serial numbers, etc.

- Jewelry and Watches: Engraving fine patterns or logos on high-precision items.

- Packaging and Labels: Marking logos, barcodes, QR codes, and other identification on packaging materials.

Software Integration:

- These machines often come with specialized vision software that enables operators to define the marking area, adjust the focal point, and fine-tune the laser parameters for specific jobs.

- The software is typically compatible with file formats such as PLT, AI, DXF, BMP, and more. It may also support real-time feedback and error detection during the marking process.

High Speed and Efficiency:

The combination of laser marking and vision systems allows for faster setup times and more consistent results, making the system highly efficient for large-scale production runs.

Advantages

- High Precision: The vision system ensures high-quality, accurate laser marking on irregular or dynamically positioned workpieces.

- Reduced Waste: By detecting misalignments or defects in real-time, the system reduces the chance of marking errors, minimizing material waste.

- Increased Efficiency: Automation of alignment and positioning leads to faster production cycles and more consistent results.

- Versatility: Can be used for a wide variety of applications, from small parts marking to large surface engravings.

- User-Friendly: The software often includes a user-friendly interface with intuitive controls for easy operation.

Typical Applications

- Barcode and QR Code Marking: Used in inventory tracking and product identification.

- Serial Number Marking: Often used for components that require unique identification.

- Logo and Text Marking: Common in manufacturing, branding, and packaging.

- Customization: Personalized engraving for items such as jewelry, gifts, or tools.

- Precision Engraving: For small, detailed designs or logos on delicate materials.

How It Works

- Camera Vision System: The machine first scans the surface of the workpiece using a high-resolution camera to capture its image. The vision system recognizes the position, size, and orientation of the object.

- Position Adjustment: Based on the camera's analysis, the machine adjusts the laser marking path to align with the object’s exact location.

- Laser Marking: The laser then marks the surface with the desired pattern, logo, text, or code, ensuring that the markings are precisely aligned, even on uneven or irregular surfaces.

Advantages Over Traditional Laser Marking Machines

- Automatic Calibration: Visual systems automatically calibrate the machine, improving accuracy and consistency.

- Versatility: Can mark irregular, misaligned, or unpositioned objects with ease, unlike traditional laser machines that require exact placement.

Higher Productivity: Automation and faster setup times reduce downtime, making it ideal for mass production.

Parameter

Description

Laser Type

Fiber Laser, UV Laser, Green Laser, CO? Laser

Laser Power

10W, 20W, 30W, 50W, 100W, etc.

Laser Wavelength

Fiber: 1064nm, UV: 355nm, CO?: 10600nm, Green: 532nm

Vision System

High-resolution camera (e.g., 2D/3D vision system)

Vision Recognition Accuracy

±0.01mm to ±0.03mm

Marking Area

100mm×100mm, 150mm×150mm, 200mm×200mm, etc.

Minimum Line Width

0.01mm

Minimum Character Height

0.1mm

Repeat Positioning Accuracy

±0.01mm

Marking Speed

Up to 8000mm/s

Cooling Method

Air Cooling or Water Cooling (depending on laser type and power)

Input Voltage

220V/50Hz or 110V/60Hz

Machine Power

< 500W (depending on laser power and model)

Operating System

Windows OS, equipped with dedicated vision marking software

Software Supported Formats

PLT, AI, DXF, BMP, JPG, PNG, etc.

Optical System

Dynamic Focusing System + High-speed Scanning Galvo + High-precision F-θ Lens

Machine Dimensions

Approx. 600mm × 500mm × 700mm

Machine Weight

Approx. 40kg to 70kg

Marking Materials

Various metals (stainless steel, aluminum, copper, etc.) and some non-metals (plastics, wood, glass, etc.)

Operating Temperature

0℃ to 40℃

Relative Humidity

10% to 85% (Non-condensing)

Tags:

Technical parameter

CO2 Flying Laser Marking Machine

Fiber laser flying inkjet printer

UV laser flying inkjet printer

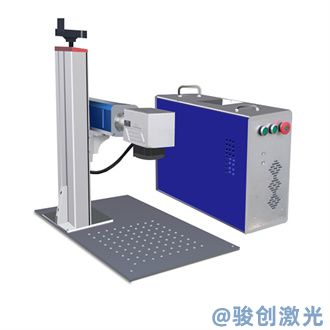

Split laser marking machine