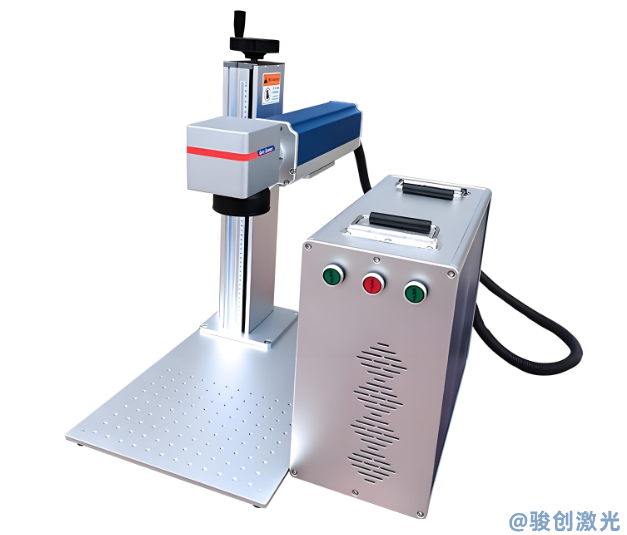

Laser marking machine is a device that uses laser beams to permanently mark various material surfaces, widely used in fields such as electronics, machinery, medical equipment, etc. It achieves fine carving of patterns, text, or QR codes through the high-temperature burning or gasification effect of laser. The main components and principles are as follows:

1. Laser

The laser is the core component of the marking machine, which determines the accuracy and effectiveness of the marking. Common types of lasers include:

Fiber laser: high stability, suitable for fine marking of metal materials.

CO ? laser: mainly used for non-metallic materials such as wood, plastic, etc.

UV laser: with a short wavelength, suitable for ultra fine marking, such as plastic casings of electronic products.

The laser generates a high-intensity, focused laser beam, which is directed towards the target surface through a focusing system.

2. galvanometer system (scanning galvanometer)

The galvanometer system consists of two high-precision mirrors (X and Y axes) controlled by servo motors, which are used to guide the laser beam to move along a specified path and achieve marking on a plane. The angle changes of these mirrors will affect the offset direction of the laser beam, thereby controlling the shape and position of the marking pattern.

Principle: The servo motor drives the angle of the mirror to change, causing the laser beam to deflect along the instructed path and form a fine pattern on the target surface.

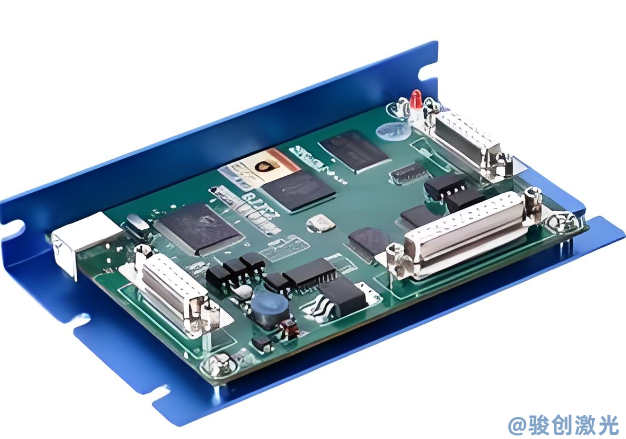

3. Control system

The control system is responsible for receiving and processing input marking instructions, including text, graphics, QR codes, etc. It converts marking information into data signals, controls the output of the laser, the movement of the galvanometer, and the marking sequence.

Principle: By processing data and outputting control signals through computer software, the deflection of the galvanometer and parameters such as laser pulse and power are controlled to form a preset pattern on the material surface according to requirements.

4. Focusing system (focusing lens)

The focusing system focuses the laser beam to a very small spot size to achieve high energy density. This process is usually completed by an F - θ mirror, which can focus the laser beam onto the same plane at different positions, thereby achieving a uniform marking effect.

Principle: Laser passes through a focusing mirror to form an extremely fine spot, generating high temperature, gasification or burning on the surface of the material in a very small area, forming clear patterns.

5. Laser power supply

Laser power supply is a device that supplies power to lasers, responsible for providing stable current and voltage. The output waveform and current magnitude of the power supply affect the power of the laser, thereby affecting the marking effect.

Principle: The power supply provides stable power to the laser, enabling it to produce stable laser output.

6. Cooling system

The cooling system is used to control the temperature of components such as lasers and mirrors, ensuring stable performance of the equipment during operation. Common cooling methods include air cooling and water cooling.

Principle: Heat is carried away by water circulation or fan to prevent power fluctuations or damage caused by laser overheating.

7. Work Platform

The work platform supports the material to be marked and can usually adjust the height to accommodate the size of different materials, ensuring that the laser is focused on the surface of the material. Some high-end laser marking machines are also equipped with automatic loading and unloading devices and rotating workbenches to achieve multi angle and complex graphic marking.

Working principle of laser marking

The basic principle of laser marking is to use a high-energy laser beam to focus on the surface of the material, causing the area to rapidly heat up, resulting in surface material gasification or carbonization, thus forming a clear marking pattern. The working process can be summarized as follows:

Laser emits beam: The laser emits a high-intensity laser beam under the command of the control system.

Vibration mirror control direction: The vibration mirror system receives control signals, and the rotation of the reflection mirror changes the direction of the laser beam.

Focusing on the surface of the material: After passing through the focusing mirror, the laser beam is focused onto the surface of the material to form an extremely small light spot.

Thermal effect marking: The material in the spot area is vaporized or discolored due to high temperature, forming text, patterns, or codes.