Products Description

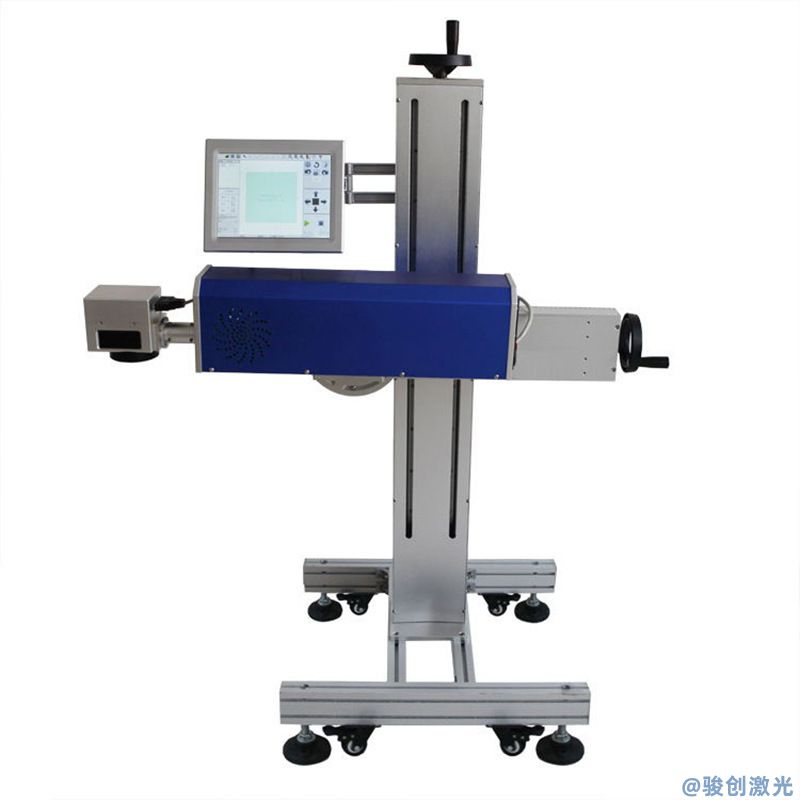

A flying laser marking machine is a high-speed, high-precision device widely used for fast marking on production lines. The process of using the machine is relatively simple but requires proper setup and adjustments to ensure optimal results. Below are the basic steps for using a flying laser marking machine:

Steps to Use a Flying Laser Marking Machine

1. Installation and Setup

- Machine Installation: First, install the flying laser marking machine in an appropriate location on the production line. Ensure that the machine is stable, and the power and air supply are connected properly.

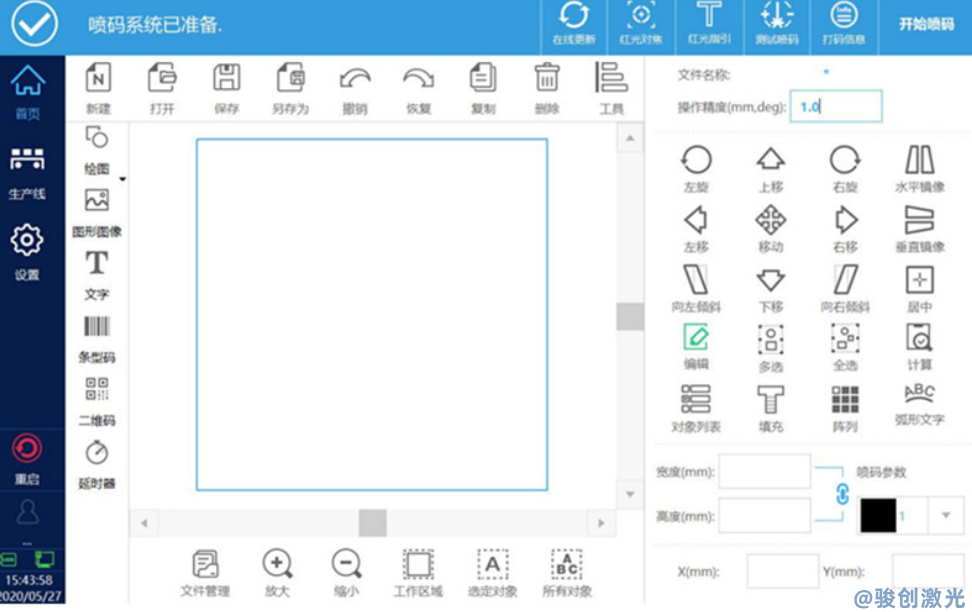

- Software Configuration: Install the machine’s software and connect it to the computer. Configure parameters such as marking content, font, size, speed, and more through the software.

Laser Head Alignment: Adjust the height and position of the laser head to ensure it is parallel to the surface of the object being marked. Focus the laser according to the specific requirements.

2. Set Up Marking Content

- Design Marking Content: Using the control software, input the information that needs to be marked, such as production dates, batch numbers, barcodes, QR codes, trademarks, or other text/images.

- Adjust Parameters: Adjust the laser power, marking speed, frequency, and other parameters according to the type of packaging material (e.g., paper box, metal, plastic). Ensure the laser marking quality is optimal and avoid excessive heating or incomplete marking.

3. Test Marking

- Dry Run: Before starting mass production, perform a dry run to ensure the laser head is aligned correctly and that the marking effect is clear. Check the test samples to ensure the markings are legible and there is no excessive thermal damage.

- Adjust Settings: Based on the test results, make necessary adjustments to the laser power, speed, and focus until the desired marking quality is achieved.

4. Production Use

- Start Production Line: Place the paper boxes or other packaging materials in the working area of the flying laser marking machine. Ensure that the materials are moving on the conveyor belt while the laser head continuously marks the correct location.

- Real-Time Marking: The flying laser marking machine will mark each product in real-time as the production line operates. The system automatically identifies the marking position and marks it according to the preset content.

5. Monitoring and Maintenance

- Real-Time Monitoring: During production, monitor the laser marking machine’s operation to ensure consistent marking quality and avoid any abnormalities.

- Regular Inspection and Cleaning: Regularly clean the laser head and other relevant components to ensure good heat dissipation and prevent dust or debris from affecting the marking effect. Additionally, check the machine's hardware regularly for necessary maintenance and upkeep.

Common Adjustments and Optimization

- Laser Power: Adjust the laser power based on the material. Harder materials (e.g., metal) typically require higher power, while softer materials (e.g., paper) need lower power.

- Marking Speed: The speed of the flying laser marking machine can be adjusted depending on production needs. Faster speeds may reduce marking quality, so finding a balance between speed and quality is important.

- Focus Adjustment: Ensure the laser head is properly focused. Fine-tune the focus based on the shape and size of the object being marked.

Precautions

- Safety: Wear appropriate protective glasses when operating the laser marking machine, and avoid direct exposure to the laser beam to ensure operator safety.

- Temperature Control: Excessive laser power may lead to overheating of the material, so it is important to ensure that the machine operates at an appropriate working temperature.

The process of using a flying laser marking machine mainly involves installation, configuration, testing, marking, and monitoring. Proper setup and operation ensure high-quality and efficient marking. With appropriate parameter adjustments, the flying laser marking machine can meet the high-precision and high-speed production needs of various industries such as packaging, electronics, and automotive.

Tags:

Technical parameter

CO2 Flying Laser Marking Machine

Fiber laser flying inkjet printer

UV laser flying inkjet printer

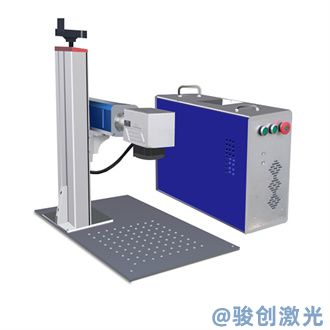

Split laser marking machine