Products Description

A flying laser marking machine used for production date coding is an efficient, precise, and eco-friendly solution widely applied in industries such as food, beverages, pharmaceuticals, cosmetics, electronics, and more. It can continuously and accurately mark production dates, batch numbers, expiration dates, and other critical information on packaging during high-speed production. Below is a detailed introduction to the flying laser marking machine for production date coding:

1. High-Precision Marking

- The flying laser marking machine can mark on various materials (such as paper boxes, plastics, metals, glass, etc.) with high precision, ensuring that production dates, batch numbers, and other information are clear, readable, and durable.

- The laser beam is extremely fine, allowing precise marking on the surface of the product packaging, guaranteeing high-quality date coding.

2. High-Speed Coding

- The flying laser marking machine is designed for high-speed production lines and can continuously mark on moving products or packaging. This makes it ideal for mass production environments.

The marking speed typically reaches thousands of characters per minute, significantly improving production efficiency and preventing bottlenecks.

3. Real-Time Marking

- Production date coding is done in real-time, synchronized with the speed of the production line. There is no need to stop or interrupt the production process.

- This real-time capability ensures that the production date information is accurate and timely, reducing the errors that may occur with manual coding.

4. Variable Data Processing

- The flying laser marking machine supports variable data input and can automatically generate different production dates, batch numbers, time stamps, etc., based on production needs.

- The machine can connect to a database or production control system, automatically generating production date information relevant to each batch of products.

5. Durable Marking

- The laser-marked data is highly durable. Unlike traditional ink coding, laser marking is not affected by external factors (such as water, oil, or friction), ensuring long-lasting clarity.

- This durability is particularly important for products with long shelf lives, such as food, pharmaceuticals, and cosmetics.

6. Non-Contact Coding

- Laser marking is a non-contact process, meaning it doesn’t exert pressure or cause damage to the packaging material. This is especially useful for fragile packaging materials like glass bottles, thin films, etc., as it avoids direct contact and ensures material integrity.

Applications

Food Industry

- Marks production dates, expiration dates, batch numbers, and other information on food packaging, ensuring that consumers are informed about the freshness and shelf life of products.

Beverage Industry

- Marks production dates, batch numbers, and expiration dates on beverage bottles and cans, helping to maintain product traceability and quality control.

Pharmaceutical Industry

- Labels production dates, expiration dates, and batch numbers on pharmaceutical packaging, ensuring compliance with regulatory requirements and helping with quality control and product traceability.

Cosmetic Industry

- Produces clear, durable markings for production dates and expiration dates on cosmetic packaging, ensuring that consumers have accurate information about product safety.

Electronics Industry

- Marks production dates, serial numbers, and other essential information on the outer packaging or labels of electronic products, aiding in inventory management and product traceability.

Advantages

High Efficiency

- The flying laser marking machine performs exceptionally well in high-speed production lines, completing coding tasks quickly and boosting overall production efficiency.

Low Maintenance Costs

- Compared to traditional coding equipment (such as inkjet printers), laser marking machines have lower maintenance costs, as they do not rely on consumables (like ink) and have a longer lifespan.

Eco-Friendly

- Laser marking does not involve using chemicals, solvents, or inks, resulting in no pollution and meeting modern sustainability and environmental standards.

Flexibility

- The flying laser marking machine can be easily adapted to different packaging materials and production environments, ensuring consistent and high-quality marking results.

High Precision

- Laser marking provides extremely high precision, making it ideal for marking small fonts, barcodes, QR codes, and other detailed information.

The flying laser marking machine used for production date coding provides an efficient, precise, durable, and eco-friendly solution. It is widely used in industries such as food, beverages, pharmaceuticals, cosmetics, and electronics, ensuring that critical information like production dates, batch numbers, and expiration dates is accurate, clear, and traceable. With its ability to work in real-time at high speeds, the flying laser marking machine has become an indispensable tool in modern manufacturing, especially for high-volume production environments.

Tags:

Technical parameter

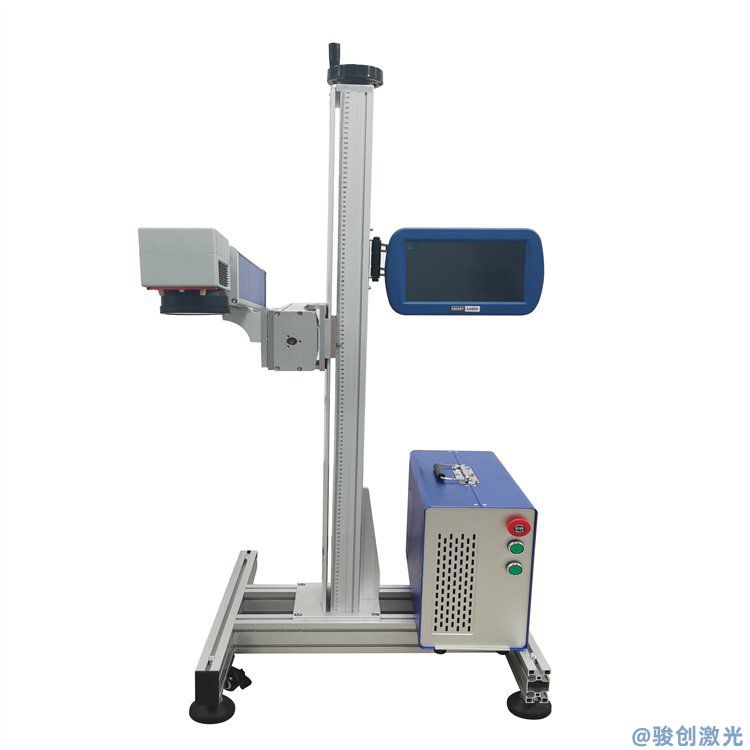

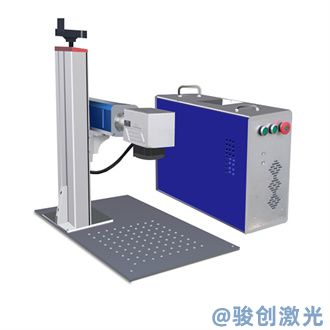

CO2 Flying Laser Marking Machine

Fiber laser flying inkjet printer

UV laser flying inkjet printer

Split laser marking machine