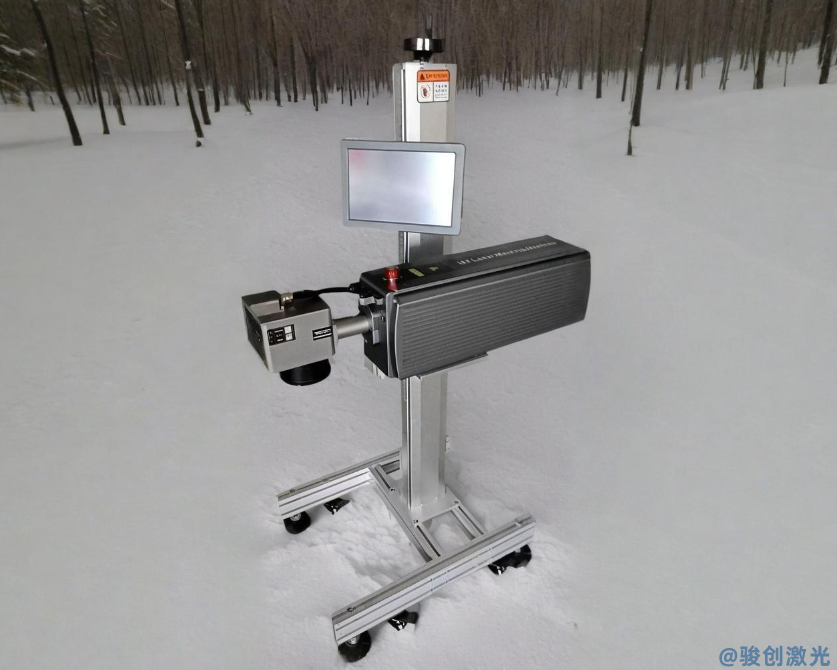

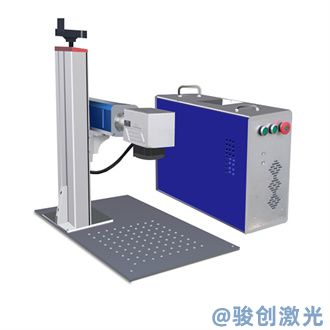

Products Description

The components of a flying laser marking machine are essential for its operation, precision control, material handling, and overall performance. Here are the common components of a flying laser marking machine:

1. Laser Source

- Function: The laser source is the core component of the flying laser marking machine, responsible for generating the laser beam. Depending on the application, the laser source may include CO2 lasers, fiber lasers, green lasers, etc.

- Purpose: It provides the powerful laser output used for marking on the target material.

2. Laser Scanning Galvo (Galvanometer)

- Function: The scanning galvo system controls the movement of the laser beam, guiding it precisely to the desired marking position.

- Purpose: It allows for high-speed and accurate scanning of the laser beam to perform marking, typically consisting of two mirrors (X-axis and Y-axis).

3. Control System

- Function: The control system acts as the brain of the machine, managing the operation interface, setting the marking content, adjusting laser parameters, and synchronizing with the production line.

- Purpose: It manages the entire marking process, including real-time data transmission, speed adjustments, and precision control.

4. Worktable

- Function: The worktable supports and positions the target material for laser marking. Depending on the needs, it may feature automatic height adjustments, rotation, or tilting capabilities to accommodate different object shapes.

- Purpose: It ensures the stability of the object being marked, maintaining a level position during the marking process.

5. High-Speed Conveying System (Flying Worktable)

- Function: In a flying laser marking machine, the conveying system moves the materials through the marking area, enabling continuous, high-speed marking.

- Purpose: It ensures stable and rapid transport of materials along the production line, preventing vibrations or misalignment that could affect marking quality.

6. Optical Lens

- Function: The optical lens focuses the laser beam, directing it onto the surface of the material being marked, ensuring precision in the marking process.

- Purpose: It adjusts the focus of the laser to ensure that the markings are sharp and accurate on the target material.

7. Cooling System

- Function: The cooling system (such as a water cooling or air cooling system) helps maintain the operating temperature of the laser marking machine, preventing overheating of the laser source and other components.

- Purpose: It ensures that the laser source works efficiently without overheating, extending the life of the machine and maintaining consistent performance.

8. Power Supply System

- Function: The power supply system provides stable electricity to all the components of the laser marking machine, ensuring reliable operation.

- Purpose: It maintains a steady power supply to avoid malfunctions and ensures the machine's consistent operation.

9. Sensors

- Function: Sensors monitor the positioning, speed, and other variables of the target material, ensuring synchronization with the production line and precise laser marking.

- Purpose: Through sensors, the flying laser marking machine can detect the position of the material in real-time, ensuring that the laser is accurately directed.

10. Rails and Frame

- Function: The rails and frame provide structural support for the laser marking machine, ensuring the stability and precision of mechanical movement.

- Purpose: They provide the physical structure of the machine, ensuring all components operate smoothly and securely during production.

11. Auto-Focus System

- Function: The auto-focus system automatically adjusts the focus of the laser beam to maintain consistent quality, even when the surface of the target material is uneven.

- Purpose: It allows for quick and automatic adjustments to the focal length to accommodate objects of varying heights.

12. Exhaust System

- Function: The exhaust system removes smoke, fumes, and harmful gases produced during the laser marking process, keeping the working environment clean and safe.

- Purpose: It clears the waste gases and smoke produced during marking, ensuring the safety of both the machine and operators.

13. Touch Screen or Interface

- Function: The touch screen or user interface allows operators to interact with the laser marking machine, configure marking settings, and monitor the machine's status.

- Purpose: It provides an intuitive interface for easy operation and control of the machine, making configuration and adjustments straightforward.

14. Laser Safety Shield

- Function: The laser safety shield protects operators from direct exposure to the laser beam.

- Purpose: It serves as a safety feature to prevent accidental exposure to harmful laser radiation, ensuring operator safety during the marking process.

A flying laser marking machine consists of various components that work together to ensure efficient operation and high-quality marking. Key components like the laser source, scanning galvo, and control system are essential for precision and speed, while other parts such as the cooling system, sensors, and worktable ensure stability and accuracy. Together, these components make flying laser marking machines ideal for high-speed, high-precision applications in industries like packaging, automotive, electronics, and more.

Tags:

Technical parameter

CO2 Flying Laser Marking Machine

Fiber laser flying inkjet printer

UV laser flying inkjet printer

Split laser marking machine