Products Description

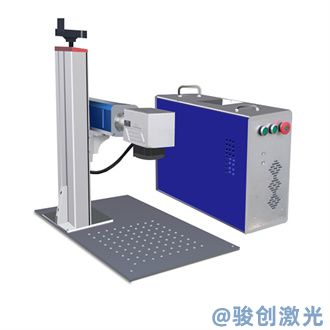

The special laser marking machine for PCB circuit boards uses ultraviolet band laser and can mark numbers, letters and Chinese characters, trademarks, LOGOs, QR codes and other contents. After our special training, it is more suitable for marking PCB circuit boards.

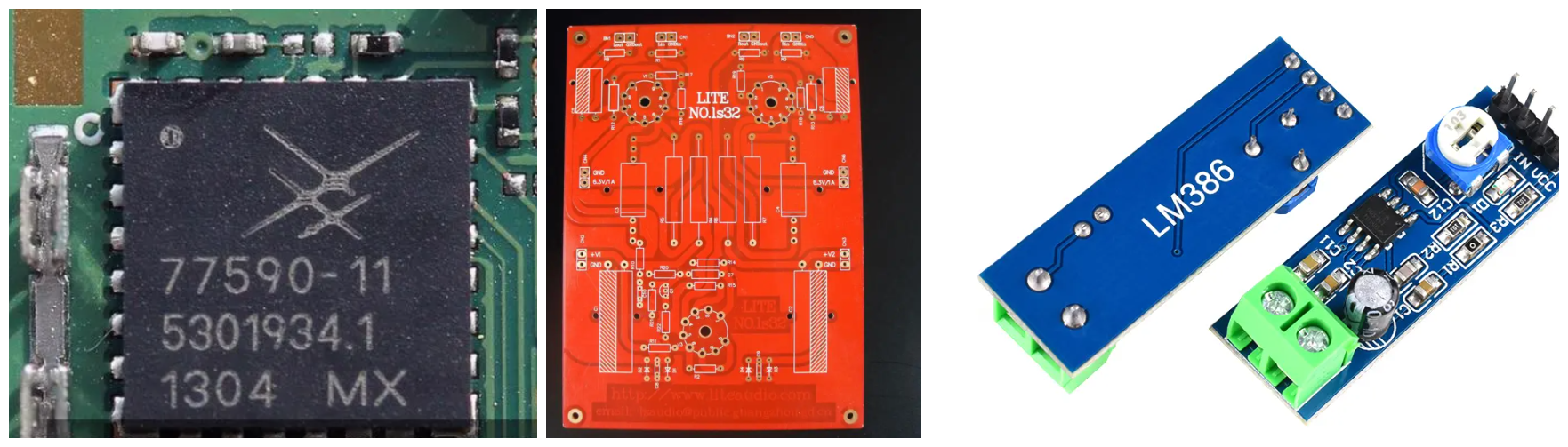

The circuit board is mainly composed of vias, connectors, mounting holes, electrical boundaries, components, pads, fillers, wires, etc. The names of circuit boards are: ceramic pcb board, ultra-thin circuit board, thick copper PCB board, PCB circuit board, PCB circuit board, aluminum substrate, high-frequency PCB board, aluminum nitride ceramic circuit board, impedance PCB board, PCB, ultra Thin circuit boards, ceramic circuit boards, printed (copper etching technology) circuit boards, etc.

parameter | SEAL | |||

Series model | 355-3 | 355-5 | 355-10S | 355-15S |

central wavelength | 355nm | |||

average power | > 3W@30kHz | > 5W@40kHz | > 10W@60kHz | > 15W@60kHz |

pulse width | < 15ns@30kHz | < 15ns@40kHz | 18ns@60kHz | |

frequency range | 20kHz-150kHz | 40kHz-300kHz | ||

spatial pattern | TEM 00 | |||

Beam quality | M2≤ 1.2 | |||

Spot roundness | > 90% | |||

Beam divergence angle | ≤ 2mrad | |||

Spot diameter | Non-expanded beam: 0.55±0.15mm | Non-expanded beam: 0.45±0.15mm | ||

Degree of polarization | > 100:1 | |||

polarization direction | level | |||

average power stability | RMS ≤ 3%@24hrs | |||

Pulse stability | RMS ≤ 3%@30kHz | RMS ≤ 3%@40kHz | RMS ≤ 3%@60kHz | |

working temperature | 0~40℃ | |||

Storage temperature | -15~50℃ | |||

Cooling method | water cooling | |||

Distribution needs | DC 12V | DC 36V | ||

average power consumption | <350W | |||

Tags:

Technical parameter

CO2 Flying Laser Marking Machine

Fiber laser flying inkjet printer

UV laser flying inkjet printer

Split laser marking machine